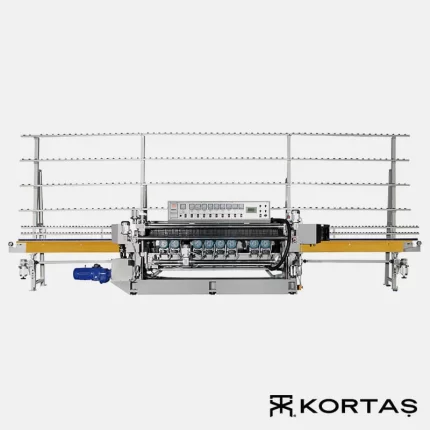

This machine works with PLC control and user interface. The glass is transported by timed belt. The conveying synchronization is quite high and the output torque remains constant. Glass working width is controlled by frequency inverter. The moving grinding section moves along the linear double ball bearing guide. Transmission is realized by double ball bearing lead screws driven by brake motor. Raising/lowering of the upper conveying system and upper arris motors is provided by motors. It can be adjusted automatically according to different glass thicknesses. Polishing wheel is controlled by air cylinder. This machine adopts high precision low vibration ABB motor. It is also equipped with automatic lubrication pump.

Double Edging Machine

This machine works with PLC control and user interface. The glass is transported by timed belt. The conveying synchronization is quite high and the output torque remains constant. Glass working width is controlled by frequency inverter. The moving grinding section moves along the linear double ball bearing guide. Transmission is realized by double ball bearing lead screws driven by brake motor. Raising/lowering of the upper conveying system and upper arris motors is provided by motors. It can be adjusted automatically according to different glass thicknesses. Polishing wheel is controlled by air cylinder. This machine adopts high precision low vibration ABB motor. It is also equipped with automatic lubrication pump.

SKU:

KRT1011

Category: Glass Processing Machines

Description