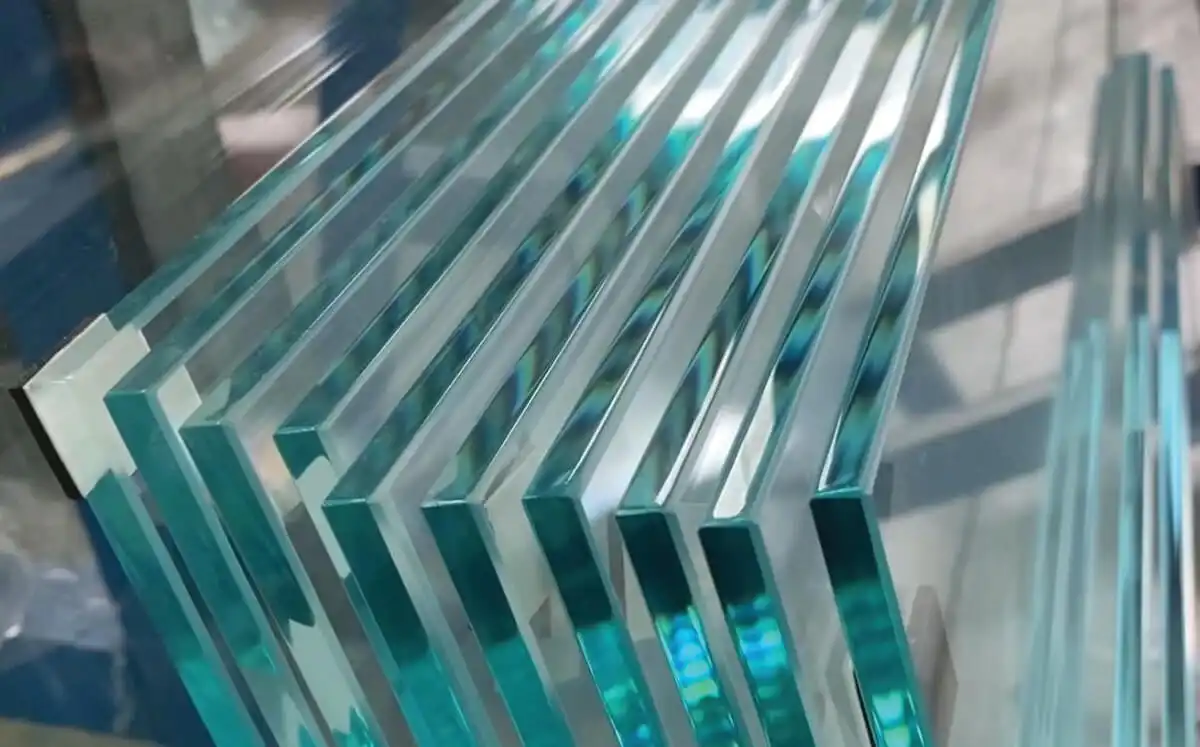

The pre-processing process of tempered glass includes steps such as cutting the glass, edge processing, drilling and washing. Glass edge processing is critical for deep glass processing. In this article, we will discuss the different aspects of the glass edging process in detail.

What is Glass Edge Processing?

Glass edging is the secondary processing of the four edges and corners of cut glass by manual or mechanical methods.

- Grinding smooth the four edges and corners resulting from the cut to prevent injuries during use.

- Grinding small cracks and micro-cracks on the edge of the glass to reduce the local stress concentration and increase the strength of the glass.

- Edge treatment reduces the possibility of glass breakage in the tempering furnace.

- After edge processing, the geometric shape and dimensional tolerances of the glass conform to the specified standards.

- The glass edge is processed at different quality levels, such as rough edging, fine edging and polishing.

- The glass surface is made suitable for coating.

Summary: Glass edge processing is important to ensure the safe use of glass, to maintain compliance with quality standards, and to comply with appearance and installation standards.